过程工程学报 ›› 2021, Vol. 21 ›› Issue (7): 762-773.DOI: 10.12034/j.issn.1009-606X.220195

收稿日期:2020-06-19

修回日期:2020-08-28

出版日期:2021-07-28

发布日期:2021-07-27

通讯作者:

赵国英 2251125219@qq.com;gyzhao@ipe.ac.cn;caihongyu2013@126.com

作者简介:胡启鲁(1995-),女,山东省茌平县人,硕士研究生,研究方向为离子材料与CO2催化转化,E-mail: 2251125219@qq.com;通讯联系人基金资助:

Qilu HU1,2( ), Guoying ZHAO2(

), Guoying ZHAO2( ), Caihong YU1(

), Caihong YU1( )

)

Received:2020-06-19

Revised:2020-08-28

Online:2021-07-28

Published:2021-07-27

Contact:

Guoying ZHAO 2251125219@qq.com;gyzhao@ipe.ac.cn;caihongyu2013@126.com

摘要:

利用丰富且价廉易得的烯烃和CO2直接反应可提供一种经济安全环保的高附加值环状碳酸酯生产工艺,具有减少CO2排放、缓解温室效应等优点。本工作以一步氧化羧化、顺序氧化羧化以及羟溴化羧化三种方法为主线,综述了近年来烯烃和CO2直接制备环状碳酸酯相关催化剂的研究进展,包括用于氧化羧化反应的催化剂,主要是同时具有烯烃环氧化催化功能和CO2羧化功能的多组分组合催化剂和多活性位点的单一催化剂,如金属氧化物、金属配合物、离子液体、改性分子筛、金属有机骨架化合物等;以及作用于羟溴化羧化反应的含Br-, I-阴离子的卤代试剂-无机/有机碱脱质子试剂组合催化剂。同时对未来烯烃和CO2制备环状碳酸酯反应的催化剂的设计及工艺开发进行了展望。

中图分类号:

胡启鲁, 赵国英, 于彩虹. 烯烃和CO2直接合成环状碳酸酯的催化剂研究进展[J]. 过程工程学报, 2021, 21(7): 762-773.

Qilu HU, Guoying ZHAO, Caihong YU. Recent advances in catalysts for direct synthesis of cyclic carbonates from olefins and CO2[J]. The Chinese Journal of Process Engineering, 2021, 21(7): 762-773.

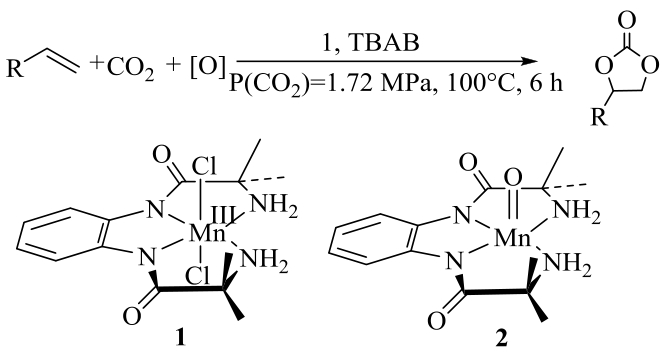

图3 新型锰(Ⅲ)配合物1和锰氧化合物中间体2的结构和反应条件[23]

Fig.3 Structure of a new manganese (Ⅲ) complex 1 and intermediate of manganese oxide compounds 2 and reaction conditions[23]

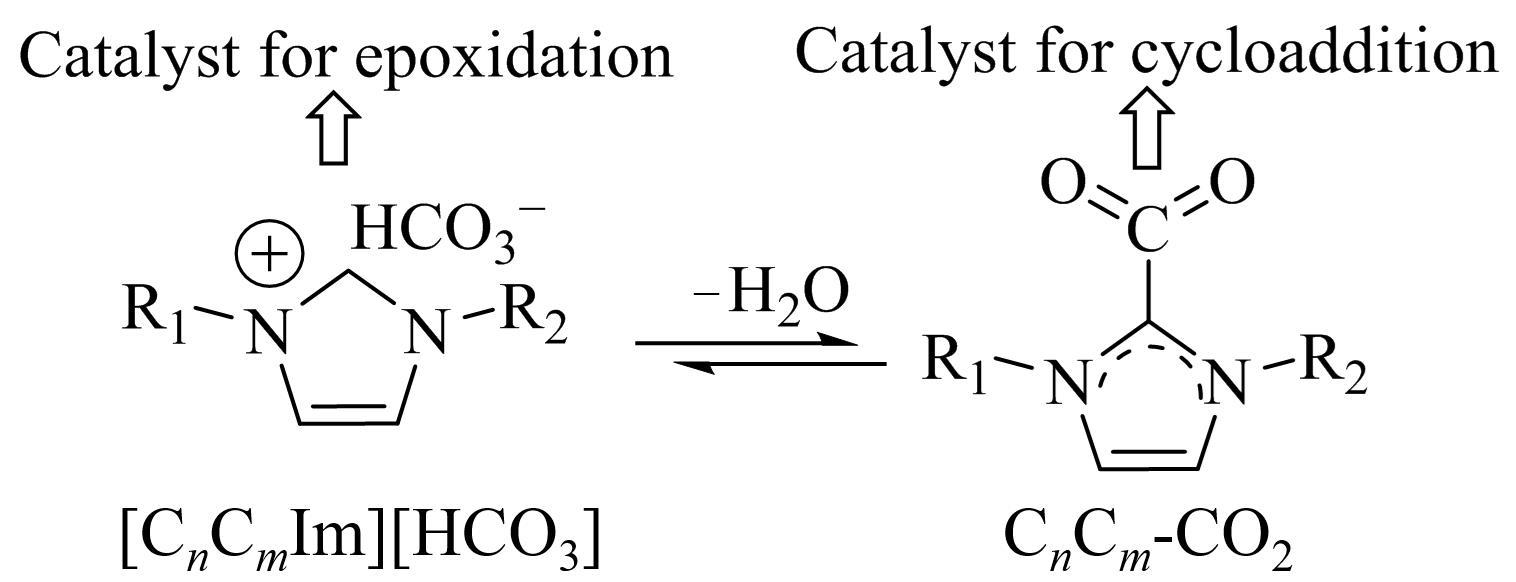

图8 催化剂[C n C m Im][HCO3]的结构和由此衍生的卡宾-CO2 (C n C m -CO2)之间的平衡[38]

Fig.8 The equilibrium between the structure of catalyst [C n C m Im][HCO3] and its derived carbene-CO2 (C n C m -CO2)[38]

| 1 | Lu X B, Darensbourg D J. Cobalt catalysts for the coupling of CO2 and epoxides to provide polycarbonates and cyclic carbonates [J]. Chemical Society Reviews, 2012, 41(4): 1462-1484. |

| 2 | Liang J, Huang Y B, Cao R, et al. Metal-organic frameworks and porous organic polymers for sustainable fixation of carbon dioxide into cyclic carbonates [J]. Coordination Chemistry Reviews, 2017, 378(SI): 32-65. |

| 3 | Sun J, Fujita S I, Zhao F, et al. A direct synthesis of styrene carbonate from styrene with the Au/SiO2-ZnBr2/Bu4NBr catalyst system [J]. Journal of Catalysis, 2005, 230(2): 398-405. |

| 4 | North M, Pasquale R, Young C, et al. Synthesis of cyclic carbonates from epoxides and CO2 [J]. Green Chemistry, 2010, 12(9): 1514-1539. |

| 5 | Cheng W G, Su Q, Wang J Q, et al. Ionic liquids: the synergistic catalytic effect in the synthesis of cyclic carbonates [J]. Catalyst, 2013, 3(4): 878-901. |

| 6 | Liu J H, Zhao G Y, Cheung O, et al. Highly porous metalloporphyrin covalent ionic frameworks with well-defined cooperative functional groups as excellent catalysts for CO2 cycloaddition [J]. Chemistry-A European Journal, 2019, 25(38): 9052-9059. |

| 7 | Sun J, Liang L, Sun J, et al. Direct synthetic processes for cyclic carbonates from olefins and CO2 [J]. Catalysis Surveys from Asia, 2011, 15(1): 49-54. |

| 8 | Xia Q, Ge H, Ye C, et al. Advances in homogeneous and heterogeneous catalytic asymmetric epoxidation [J]. Chemical Reviews, 2005, 105(5): 1603-1662. |

| 9 | Amarajothi D, Hermenegildo G. Cascade reactions catalyzed by metal organic frameworks [J]. Chemsuschem, 2014, 7(9): 2392-2410. |

| 10 | 李享. 以CO2与烯烃为原料合成丁二酸和环状碳酸酯的研究[D]. 广州: 华南理工大学, 2019: 10. |

| Li H. Study on the synthesis of succinic acid and cyclic carbonate from CO2 and olefins [D]. Guangzhou: South China University of Technology, 2019: 10. | |

| 11 | 刘宝航, 王伟建. 二氧化碳加氢合成低碳烯烃催化剂的研究进展 [J]. 安徽化工, 2019, 45(5): 11-14, 17. |

| Liu B H, Wang W J. Research progress of catalysts for hydrogenation of carbon dioxide to low olefins [J]. Anhui Chemical Industry, 2019, 45(5): 11-14, 17. | |

| 12 | Bajracharya S, Srikanth S, Mohanakrishna G, et al. Biotransformation of carbon dioxide in bioelectrochemical systems: state of the art and future prospects [J]. Journal of Power Sources, 2017, 356(15): 256-273. |

| 13 | Wang J, Petit C, Zhang X, et al. Simultaneous measurement of CO2 sorption and swelling of phosphate-based ionic liquid [J]. Green Energy & Environment, 2016, 1(3): 258-265. |

| 14 | 刘佳慧, 刘会婷, 赵国英, 等. 离子液体自模板合成多孔碳氮材料及其对二氧化碳的吸附 [J]. 过程工程学报, 2020, 20(1): 108-115. |

| Liu J H, Liu H T, Zhao G Y, et al. Ionic liquids self-templating to synthesize nitrogen-doped porous carbon materials for CO2 adsorption [J]. The Chinese Journal of Process Engineering, 2020, 20(1): 108-115. | |

| 15 | Tebandeke E, Coman C, Guillois K, et al. Epoxidation of olefins with molecular oxygen as the oxidant using gold catalysts supported on polyoxometalates [J]. Green Chemistry, 2014, 16(3): 1586-1593. |

| 16 | Suttikul T, Paosombat B, Santikunaporn M, et al. Improvement of ethylene epoxidation in a parallel plate dielectric barrier discharge system by ethylene/oxygen separate feed and Ag catalyst [J]. Industrial and Engineering Chemistry Research, 2014, 53(10): 3778-3786. |

| 17 | 邹波. 从烯烃出发合成环状碳酸酯研究 [D]. 北京: 北京理工大学, 2016: 15. |

| Zou B. Study on the synthesis of cyclic carbonate from olefin [D]. Beijing: Beijing University of Technology, 2016: 15. | |

| 18 | Kohno K, Sakakura T. Catalytic transformation of carbon dioxide to organic carbonates [J]. ChemInform, 2009, 67(9): 921-933. |

| 19 | Song Q W, Zhou Z H, He L N. Efficient, selective and sustainable catalysis of carbon dioxide [J]. Green Chemistry, 2017, 19(16): 3707-3728. |

| 20 | Liu Q, Wu L, Jackstell R, et al. Using carbon dioxide as a building block in organic synthesis [J]. Nature Communications, 2015, 47(13): 5933. |

| 21 | Sankar M, Tarte N H, Manikandan P. Effective catalytic system of zinc-substituted polyoxometalate for cycloaddition of CO2 to epoxides [J]. Applied Catalysis A: General, 2004, 276(1/2): 217-222. |

| 22 | Bai D S, Jing H Q. Aerobic oxidative carboxylation of olefins with metalloporphyrin catalysts [J]. Green Chemistry, 2009, 12(1): 39-41. |

| 23 | Ramidi P, Felton C M, Subedi B P, et al. Synthesis and characterization of manganese(III) and high-valent manganese-oxo complexes and their roles in conversion of alkenes to cyclic carbonates [J]. Journal of CO2 Utilization, 2015, 9: 48-57. |

| 24 | Abassian M, Zhiani R, Motavalizadehkakhky A, et al. A new class of organoplatinum-based DFNS for the production of cyclic carbonates from olefins and CO2 [J]. RSC Advances, 2020, 10, 15044-15051. |

| 25 | Zhang S, Xia Z M, Zou Y, et al. Interfacial frustrated lewis pairs of CeO2 activate CO2 for selective tandem transformation of olefins and CO2 into cyclic carbonates [J]. Journal of the American Chemical Society, 2019, 141(29): 11353-11357. |

| 26 | Dumbre D K, Choudhary V R, Patil N S, et al. Calcium oxide supported gold nanoparticles as catalysts for the selective epoxidation of styrene by t-butyl hydroperoxide [J]. Journal of Colloid and Interface Science, 2014, 415: 111-116. |

| 27 | Sun J M, Fujita S I, Zhao F Y, et al. A direct synthesis of styrene carbonate from styrene with the Au/SiO2-ZnBr2/Bu4NBr catalyst system [J]. Journal of Catalysis, 2005, 230(2): 398-405. |

| 28 | Wang Y L, Sun J H, Xiang D, et al. A facile, direct synthesis of styrene carbonate from styrene and CO2 catalyzed by Au/Fe(OH)3-ZnBr2/Bu4NBr system [J]. Catalysis Letters, 2009, 129(3/4): 437-443. |

| 29 | Maksimchuk N V, Ivanchikova I D, Ayupov A B, et al. One-step solvent-free synthesis of cyclic carbonates by oxidative carboxylation of styrenes over a recyclable Ti-containing catalyst [J]. Applied Catalysis B Environmental, 2016, 181: 363-370. |

| 30 | Gu B B, Xu T, Xu G R, et al. Synthesis of styrene carbonate from styrene and CO2 catalyzed by walnut-like zeolite LZ-276 [J]. Microporous and Mesoporous Materials, 2020, 293: 109779. |

| 31 | Zalomaeva O V, Maksimchuk N V, Chibiryaev A M, et al. Synthesis of cyclic carbonates from epoxides or olefins and CO2 catalyzed by metal-organic frameworks and quaternary ammonium salts [J]. Journal of Energy Chemistry, 2013, 22(1): 130-135. |

| 32 | Nguyen P T K, Nguyen H T D, Nguyen H N, et al. New metal-organic frameworks for chemical fixation of CO2 [J]. ACS Applied Materials & Interfaces, 2018, 10(1): 733-744. |

| 33 | Nguyen H T D, Tran Y B N, Nguyen H N, et al. A series of metal-organic frameworks for selective CO2 capture and catalytic oxidative carboxylation of olefins [J]. Inorganic Chemistry, 2018, 57(21): 13772-13782. |

| 34 | Sharma N, Dhankhar S S, Kumar S, et al. Rational design of 3D Mn(II)-metal organic framework based on non-metallated porphyrin linker for selective capture of CO2 and one-pot synthesis of styrene carbonates [J]. Chemistry-A European Journal, 2018, 24(62): 16662-16669. |

| 35 | Aresta M, Quaranta E, Ciccarese A, et al. Direct synthesis of 1,3-benzodioxol-2-one from styrene, dioxygen and carbon-dioxide promoted by Rh(I) [J]. Journal of Molecular Catalysis, 1987, 41(3): 355-359. |

| 36 | Aresta M, Dibenedetto A, Tommasi I, et al. Direct synthesis of organic carbonates by oxidative carboxylation of olefins catalyzed by metal oxides: developing green chemistry based on carbon dioxide [J]. Applied Organometallic Chemistry, 2000, 14(12): 799-802. |

| 37 | Aresta M, Dibenedetto A. Carbon dioxide as building block for the synthesis of organic carbonates [J]. Molecular Catalysis, 2002, 182(1): 399-409. |

| 38 | Liu J, Yang G Q, Liu Y, et al. Metal-free imidazolium hydrogen carbonate ionic liquids as bifunctional catalysts for the one-pot synthesis of cyclic carbonates from olefins and CO2 [J]. Green Chemistry, 2019, 21(14): 3834-3838. |

| 39 | Kumar S, Singhal N, Singh R K, et al. Dual catalysis with magnetic chitosan: direct synthesis of cyclic carbonates from olefins with carbon dioxide using isobutyraldehyde as the sacrificial reductant [J]. Dalton Transactions, 2015, 44(26): 11860-11866. |

| 40 | Huang Z J, Li F B, Chen B F, et al. Well-dispersed g-C3N4 nanophases in mesoporous silica channels and their catalytic activity for carbon dioxide activation and conversion [J]. Applied Catalysis B Environmental, 2013, 136: 269-277. |

| 41 | Han Q X, Qi B, Ren W M, et al. Polyoxometalate-based homochiral metal-organic frameworks for tandem asymmetric transformation of cyclic carbonates from olefins [J]. Nature Communications, 2015, 6: 10007. |

| 42 | Yu K, Puthiaraj P, Ahn W S. One-pot catalytic transformation of olefins into cyclic carbonates over an imidazolium bromide-functionalized Mn(III)-porphyrin metal-organic framework [J]. Applied Catalysis B: Environmental, 2020, 273: 119059. |

| 43 | Chen F W, Dong T, Xu T G, et al. Direct synthesis of cyclic carbonates from olefins and CO2 catalyzed by a MoO2(acac)2-quaternary ammonium salt system [J]. Green Chemistry, 2011, 13(9): 2518-2524. |

| 44 | Siewniak A, Jasiak-Jaron K, Kotyrba L, et al. Efficient catalytic system involving molybdenyl acetylacetonate and immobilized tributylammonium chloride for the direct synthesis of cyclic carbonates from carbon dioxide and olefins [J]. Catalysis Letters, 2017, 147(6): 1567-1573. |

| 45 | Dias L D, Carrilho R M B, Henriques C A, et al. Hybrid-metalloporphyrin magnetic nanoparticles as catalysts for sequential transformation of alkenes and CO2 into cyclic carbonates [J]. ChemCatChem, 2018, 10(13): 2792-2803. |

| 46 | Engel R V, Alsaiari R, Nowicka E, et al. Oxidative carboxylation of 1-decene to 1,2-decylene carbonate [J]. Topics in Catalysis, 2018, 61(5/6): 509-518. |

| 47 | Xiang D, Liu X F, Sun J S, et al. A novel route for synthesis of styrene carbonate using styrene and CO2 as substrates over basic resin R201 supported Au catalyst [J]. Catalysis Today, 2009, 148(3/4): 383-388. |

| 48 | Srivastava R, Srinivas D, Ratnasamy P. Synthesis of polycarbonate precursors over titanosilicate molecular sieves [J]. Catalysis Letters, 2003, 91(1/2): 133-139. |

| 49 | Shi Z L, Niu G Q, Han Q X, et al. A molybdate-incorporated cooperative catalyst: high efficiency in the assisted tandem catalytic synthesis of cyclic carbonates from CO2 and olefins [J]. Molecular Catalysis, 2018, 461: 10-18. |

| 50 | Ke S C, Luo T T, Chang G G, et al. Spatially ordered arrangement of multifunctional sites at molecule level in a single catalyst for tandem synthesis of cyclic carbonates [J]. Inorganic Chemistry, 2020, 59(3): 1736-1745. |

| 51 | Zhao G D, Zhang Y, Zhang H Y, et al. Direct synthesis of propylene carbonate from propylene and carbon dioxide catalyzed by quaternary ammonium heteropolyphosphatotungstate-TBAB system [J]. Journal of Energy Chemistry, 2015, 24(3): 353-358. |

| 52 | 刘伟, 钱静怡, 曹新宇, 等. 用于烯烃环氧化反应的甲基三氧化铼催化体系的研究进展 [J]. 吉林师范大学学报(自然科学版), 2018, 39(4): 30-35. |

| Liu W, Qian J Y, Cao X Y, et al. The research progress in catalytic system of methyltrioxorhenium for olefin epoxidation [J]. Journal of Jilin Normal University (Natural Science Edition), 2018, 39(4): 30-35. | |

| 53 | Ono F, Qiao K, Tomida D, et al. Direct preparation of styrene carbonates from styrene using an ionic liquid-based one-pot multistep synthetic process [J]. Applied Catalysis A: General, 2007, 333(1): 107-113. |

| 54 | Sathe A A, Nambiar A M K, Rioux R M, et al. Synthesis of cyclic organic carbonates via catalytic oxidative carboxylation of olefins in flow reactors [J]. Catalysis Science & Technology, 2016, 7(1): 84-89. |

| 55 | Zhang J, Liu Y M, Li N N, et al. Synthesis of propylene carbonate on a bifunctional titanosilicate modified with quaternary ammonium halides [J]. Chinese Journal of Catalysis, 2008, 29(7): 589-591. |

| 56 | Sun J M, Fujita S I, Bhanage B M, et al. One-pot synthesis of styrene carbonate from styrene in tetrabutylammonium bromide [J]. Catalysis Today, 2004, 93/94/95: 383-388. |

| 57 | 孙建敏, 王亚丽, 屈学俭, 等.溴化四丁铵催化苯乙烯一步合成苯乙烯环状碳酸酯 [J]. 高等学校化学学报, 2006, 4(8): 1522-1525. |

| Sun J M, Wang Y L, Qu X J, et al. New route to direct synthesis styrene carbonate from styrene catalyzed by quaternary ammonium bromide [J]. Chemical Journal of Chinese Universities, 2006, 4(8): 1522-1525. | |

| 58 | Wang J L, Wang J Q, He L N, et al. A CO2/H2O2-tunable reaction: direct conversion of styrene into styrene carbonate catalyzed by sodium phosphotungstate/n-Bu4NBr [J]. Green Chemistry, 2008, 10(11): 1218-1223. |

| 59 | Girard A L, Simon N, Zanatta M, et al. Insights on recyclable catalytic system composed of task-specific ionic liquids for the chemical fixation of carbon dioxide [J]. Green Chemistry, 2014, 16(5): 2815-2825. |

| 60 | Yang X Q, Wu J, Mao X W, et al. Microwave assisted synthesis of cyclic carbonates from olefins with sodium bicarbonates as the C1 source [J]. Chemical Communications, 2014, 50(24): 3245-3248. |

| 61 | Xie J N, Diao Z F, Qiao C, et al. One-pot stepwise synthesis of cyclic carbonates directly from olefins with CO2 promoted by K2S2O8/NaBr [J]. Journal of CO2 Utilization, 2016, 16: 313-317. |

| 62 | Gao X F, Yuan G Q, Chen H J, et al. Efficient conversion of CO2 with olefins into cyclic carbonates via a synergistic action of I2 and base electrochemically generated in situ [J]. Electrochemistry Communications, 2013, 34: 242-245. |

| 63 | Eghbali N, Li C J. Conversion of carbon dioxide and olefins into cyclic carbonates in water [J]. Green Chemistry, 2007, 9(3): 213-215. |

| 64 | Davies S G, Fletcher A M, Kurosawa W, et al. One-pot conversions of olefins to cyclic carbonates and secondary allylic and homoallylic amines to cyclic carbamates [J]. Journal of Organic Chemistry, 2010, 75(22): 7745-7756. |

| 65 | Wu J, Kozak J A, Simeon F, et al. Mechanism-guided design of flow systems for multicomponent reactions: conversion of CO2 and olefins to cyclic carbonates [J]. Chemical Science, 2014, 5(3): 1227-1231. |

| [1] | 靳波 张亚新. 颗粒尺度下混合催化剂床层中CO2加氢反应体系数值模拟[J]. 过程工程学报, 2022, 22(8): 1040-1052. |

| [2] | 张凯伦 焦念明 张莹 郝鹏波 张国霞 王慧 李增喜. 双金属改性ZSM-5-USY复合分子筛催化裂解正己烷制备低碳烯烃[J]. 过程工程学报, 2022, 22(4): 458-468. |

| [3] | 洪坤 曹曼倩 王文轩 高亚男. 甲醇制烯烃流化床内流化特性的多尺度CFD模拟[J]. 过程工程学报, 2021, 21(9): 1012-1022. |

| [4] | 张卫风 李娟 王秋华. 响应面法优化解吸MDEA/PG富液中CO2再生工艺[J]. 过程工程学报, 2021, 21(3): 353-362. |

| [5] | 郭艳东 贺艳静 张晓春. 离子液体-氧化石墨烯膜材料在CO2分离领域的研究进展[J]. 过程工程学报, 2021, 21(12): 1373-1382. |

| [6] | 周玥 郭晓晶 李宣江 高璐 洪枫 乔锦丽. 不同浸渍时间对CuO/Cu@BC电极催化CO2还原性能的影响[J]. 过程工程学报, 2020, 20(8): 989-996. |

| [7] | 孙灵 诸林 何阳东. 基于链式循环二氧化碳重整的甲烷制甲醇过程火用分析[J]. 过程工程学报, 2020, 20(7): 822-831. |

| [8] | 刘佳慧 刘会婷 赵国英 孙振宇. 离子液体自模板合成多孔碳氮材料及其对二氧化碳的吸附[J]. 过程工程学报, 2020, 20(1): 108-115. |

| [9] | 李金平 李洋 姚泽 张学民 黄娟娟 康健. 初始压力对冰冻石英砂中CO2水合物生成特性的影响[J]. 过程工程学报, 2019, 19(1): 216-222. |

| [10] | 郭亚楼 张辉 刘应书 赵梓伶 张宣凯 李东. 升温速率对CO2在13X分子筛上脱附性能的影响[J]. 过程工程学报, 2018, 18(1): 88-95. |

| [11] | 袁聪聪 王宇栋 张丁川 杨斌 戴永年. 木屑颗粒热解过程动力学计算及热解气体分析[J]. 过程工程学报, 2017, 17(5): 1102-1108. |

| [12] | 李露 王晓春 杨冬伟 王琴 施锦. CO2在四丁基高氯酸铵-碳酸丙烯酯溶液中的电催化还原[J]. 过程工程学报, 2015, 15(5): 837-841. |

| [13] | 张贺 张辉. 刘应书 郝智天 赵梓伶 郭亚楼. 二乙醇胺溶液吸收CO2过程[J]. 过程工程学报, 2015, 15(5): 774-780. |

| [14] | 冯妙娜 盖健楠 赵国英 高洪苓 张锁江. 软模板法用壳聚糖制备富氮多孔碳材料[J]. 过程工程学报, 2015, 15(3): 536-540. |

| [15] | 王晓春 李露 杨冬伟 王琴 施锦. Au和Ag电极上CO2电还原反应的动力学特征对比[J]. , 2014, 14(6): 961-966. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||