过程工程学报 ›› 2021, Vol. 21 ›› Issue (7): 752-761.DOI: 10.12034/j.issn.1009-606X.220208CSTR: 32067.14.jproeng.220208

王娟1,2( ), 徐皓晗1,2, 解凯1,2, 余海艳1,2

), 徐皓晗1,2, 解凯1,2, 余海艳1,2

收稿日期:2020-07-01

修回日期:2020-08-26

出版日期:2021-07-28

发布日期:2021-07-27

作者简介:王娟(1977-),女,辽宁省丹东市人,博士,副教授,化工过程机械,E-mail: wangjuan@cup.edu.cn.

Juan WANG1,2( ), Haohan XU1,2, Kai XIE1,2, Haiyan YU1,2

), Haohan XU1,2, Kai XIE1,2, Haiyan YU1,2

Received:2020-07-01

Revised:2020-08-26

Online:2021-07-28

Published:2021-07-27

摘要: 随着乙烯工业的不断发展及能源结构的不断调整,裂解乙烯原料呈现多样性。近年来,乙烷裂解制乙烯技术逐渐成为工业生产的热点。乙烷作为乙烯生产的优选原料,不仅具有收率高、纯度高、质量高的产品优势,同时具有投资低、成本低、能耗低的生产优势。作为裂解炉模拟的核心,研究乙烷裂解过程中的反应动力学模型可为工业生产提供精准预判。随工业应用范围的逐步扩大,该领域的理论研究也将迎来新的高潮。本工作对乙烷裂解的工艺优势、乙烷裂解反应动力学模型及结焦反应动力学模型的研究现状进行了总结。裂解反应动力学模型被分为经验模型、机理模型、分子反应动力学模型,结焦反应动力学模型被分为催化结焦、自由基结焦。针对未来的研究方向提出了新的展望,认为经验模型在裂解炉自动控制中的应用、自由基反应动力学模型的深入研究、乙烷与其他原料的共裂过程、裂解反应动力学与CFD技术的融合及基于多种生成机理建立结焦反应动力学模型五个方面将是今后需要关注的领域。

中图分类号:

王娟, 徐皓晗, 解凯, 余海艳. 乙烷裂解制乙烯过程反应动力学模型的研究进展[J]. 过程工程学报, 2021, 21(7): 752-761.

Juan WANG, Haohan XU, Kai XIE, Haiyan YU. Research progress on kinetic models of ethane pyrolysis[J]. The Chinese Journal of Process Engineering, 2021, 21(7): 752-761.

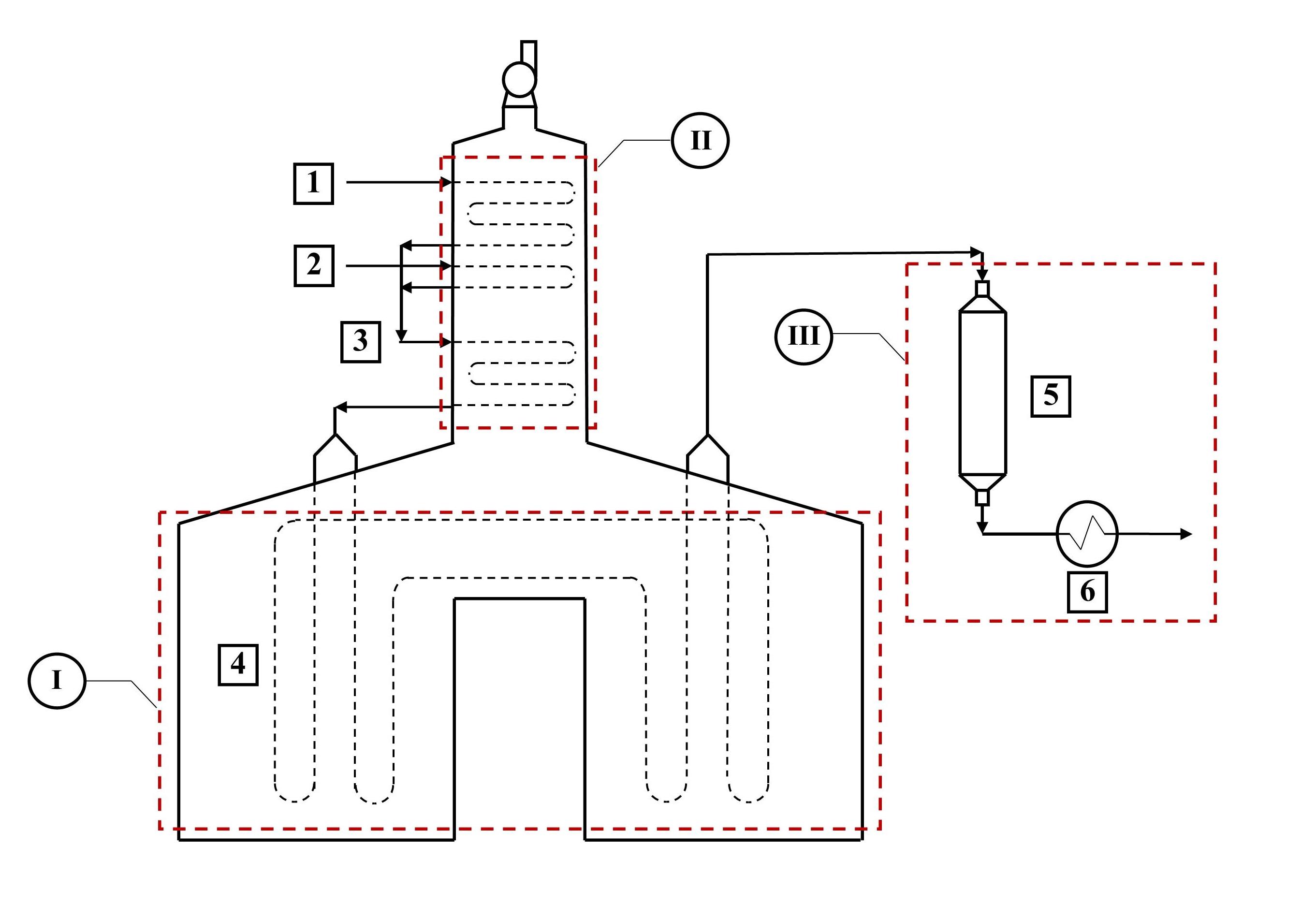

图1 典型乙烷炉示意图[12]I. Radiant section II. Convection section III. Cooling section 1. Ethane feed inlet 2. Dilution steam inlet 3. Mixed feed inlet4. Furnace tubes 5. Ultra-selective exchanger 6. Transfer-line exchanger

Fig.1 Schematic diagram of a typical ethane furnace[12]

| Furnace type | Gas furnace | Liquid furnace |

|---|---|---|

| Cracking raw materials | Ethane propane | Naphtha ethane propane |

| Radiant section furnace tube form | Four tubes or six tubes | Two tubes |

| Dilution steam heating coil | No | Yes |

| Raw material preheating two-stage coil | No | Yes |

| Quench heat exchanger | Level 1, Level 2, Level 3 | Level 1 |

| Burner fuel | Hydrogen-rich fuel (hydrogen content greater than 60%) | Methane hydrogen (20% hydrogen) fuel |

表1 裂解炉配置比较[16]

Table 1 Comparison of cracking furnace configuration[16]

| Furnace type | Gas furnace | Liquid furnace |

|---|---|---|

| Cracking raw materials | Ethane propane | Naphtha ethane propane |

| Radiant section furnace tube form | Four tubes or six tubes | Two tubes |

| Dilution steam heating coil | No | Yes |

| Raw material preheating two-stage coil | No | Yes |

| Quench heat exchanger | Level 1, Level 2, Level 3 | Level 1 |

| Burner fuel | Hydrogen-rich fuel (hydrogen content greater than 60%) | Methane hydrogen (20% hydrogen) fuel |

| Feedstocks | H2 | CH4 | C2H4 | C3H8 | 1,3-butadiene | C4H10+C4H8 | Benzene |

|---|---|---|---|---|---|---|---|

| Ethane | 8.82 | 6.27 | 77.73 | 2.76 | 1.81 | 1.81 | 0.87 |

| Propane | 2.27 | 27.43 | 42.01 | 16.82 | 3.01 | 3.01 | 2.47 |

| N-butane | 1.57 | 22.12 | 40.00 | 17.27 | 3.50 | 3.50 | 3.02 |

| Naphtha | 1.56 | 17.20 | 33.62 | 15.53 | 4.56 | 4.56 | 6.74 |

| Atmospheric diesel | 0.94 | 11.19 | 25.92 | 16.15 | 4.56 | 4.56 | 6.03 |

| Vacuum residue | 0.78 | 8.75 | 20.49 | 14.07 | 5.38 | 5.38 | 3.73 |

表2 不同裂解原料的主要产品分布(wt%)[17]

Table 2 Product distribution of different cracking raw materials (wt%)[17]

| Feedstocks | H2 | CH4 | C2H4 | C3H8 | 1,3-butadiene | C4H10+C4H8 | Benzene |

|---|---|---|---|---|---|---|---|

| Ethane | 8.82 | 6.27 | 77.73 | 2.76 | 1.81 | 1.81 | 0.87 |

| Propane | 2.27 | 27.43 | 42.01 | 16.82 | 3.01 | 3.01 | 2.47 |

| N-butane | 1.57 | 22.12 | 40.00 | 17.27 | 3.50 | 3.50 | 3.02 |

| Naphtha | 1.56 | 17.20 | 33.62 | 15.53 | 4.56 | 4.56 | 6.74 |

| Atmospheric diesel | 0.94 | 11.19 | 25.92 | 16.15 | 4.56 | 4.56 | 6.03 |

| Vacuum residue | 0.78 | 8.75 | 20.49 | 14.07 | 5.38 | 5.38 | 3.73 |

| Project | Ethane | Propane | Butane | Light naphtha | Light diesel oil | Vacuum gas oil |

|---|---|---|---|---|---|---|

| Investment/USD million | 413.5 | 508.5 | 516.2 | 554.1 | 644.4 | 668.1 |

| Relative investment | 1.00 | 1.25 | 1.25 | 1.34 | 1.56 | 1.62 |

| Cost/(USD/t) | 241.9 | 201.5 | 201.8 | 355.3 | 397.3 | 363.5 |

| Relative energy consumption | 1.00 | 1.44 | 1.50 | 1.53 | 1.72 | 2.04 |

表3 不同裂解原料的乙烯装置投资、成本和相对能耗比较[18]

Table 3 Comparison of ethylene plant investment, cost and relative energy consumption with different cracking raw materials[18]

| Project | Ethane | Propane | Butane | Light naphtha | Light diesel oil | Vacuum gas oil |

|---|---|---|---|---|---|---|

| Investment/USD million | 413.5 | 508.5 | 516.2 | 554.1 | 644.4 | 668.1 |

| Relative investment | 1.00 | 1.25 | 1.25 | 1.34 | 1.56 | 1.62 |

| Cost/(USD/t) | 241.9 | 201.5 | 201.8 | 355.3 | 397.3 | 363.5 |

| Relative energy consumption | 1.00 | 1.44 | 1.50 | 1.53 | 1.72 | 2.04 |

| Reaction stage | Primitive reaction | A/ [m3/(mol∙s)] | E/(kcal/mol) |

|---|---|---|---|

| Chain initiation | C2H6→2CH3* | 6.3×1016 | 86.0 |

| Chain growth | CH3*+C2H6→CH4+C2H5* | 2.5×1011 | 10.8 |

| C2H5*→C2H4+H* | 5.3×1014 | 40.8 | |

| H*+C2H6→C2H5*+H2 | 3.8×1012 | 7.0 | |

| Chain termination | H*+C2H5*→C2H6 | 7.0×1013 | 0.0 |

表4 乙烷裂解自由基机理[29]

Table 4 Radical mechanics of ethane cracking[29]

| Reaction stage | Primitive reaction | A/ [m3/(mol∙s)] | E/(kcal/mol) |

|---|---|---|---|

| Chain initiation | C2H6→2CH3* | 6.3×1016 | 86.0 |

| Chain growth | CH3*+C2H6→CH4+C2H5* | 2.5×1011 | 10.8 |

| C2H5*→C2H4+H* | 5.3×1014 | 40.8 | |

| H*+C2H6→C2H5*+H2 | 3.8×1012 | 7.0 | |

| Chain termination | H*+C2H5*→C2H6 | 7.0×1013 | 0.0 |

| Froment | Zou | ||||

|---|---|---|---|---|---|

| Cracking reaction system | Ethane | Propane | Ethane-propane | Ethane-propane | |

| Number of reactions | 49 | 80 | 17 | 18 | |

| Number of species | Molecule | 11 9 | 11 11 | 6 6 | 6 5 |

| Free radicals | |||||

| Number of parameters | 81 | 134 | 32 | 34 | |

| Pseudo-steady state hypothesis | No | No | No | No | |

| Valuation method | Try method | Try method | Taken from the separate pyrolysis system | Improved simplex algorithm | |

表5 各自由基机理模型设置[33]

Table 5 Comparison of various free radical mechanism models[33]

| Froment | Zou | ||||

|---|---|---|---|---|---|

| Cracking reaction system | Ethane | Propane | Ethane-propane | Ethane-propane | |

| Number of reactions | 49 | 80 | 17 | 18 | |

| Number of species | Molecule | 11 9 | 11 11 | 6 6 | 6 5 |

| Free radicals | |||||

| Number of parameters | 81 | 134 | 32 | 34 | |

| Pseudo-steady state hypothesis | No | No | No | No | |

| Valuation method | Try method | Try method | Taken from the separate pyrolysis system | Improved simplex algorithm | |

| No. | Reaction | ΔH/(kcal/mol) |

|---|---|---|

| 1 | C2H6↔C2H4+H2 | 3.257×107 |

| 2 | 2C2H6→C3H8+CH4 | -2.761×106 |

| 3 | C3H6↔C2H2+CH4 | 3.188×107 |

| 4 | C2H2+C2H4 →C4H6 | -4.173×106 |

| 5 | C2H6+C2H4→C3H6+CH4 | -5.489×106 |

表6 乙烷裂解的反应方案[46]

Table 6 Reaction scheme for ethane cracking[46]

| No. | Reaction | ΔH/(kcal/mol) |

|---|---|---|

| 1 | C2H6↔C2H4+H2 | 3.257×107 |

| 2 | 2C2H6→C3H8+CH4 | -2.761×106 |

| 3 | C3H6↔C2H2+CH4 | 3.188×107 |

| 4 | C2H2+C2H4 →C4H6 | -4.173×106 |

| 5 | C2H6+C2H4→C3H6+CH4 | -5.489×106 |

| No. | Reaction | ΔH/(kcal/mol) |

|---|---|---|

| 1 | C2H6↔C2H4+H2 | 3.257×107 |

| 2 | 2C2H6→C3H8+CH4 | -2.761×106 |

| 3 | C3H8→C3H6+H2 | 2.984×107 |

| 4 | C3H8→C2H4+CH4 | 1.974×107 |

| 5 | C3H6↔C2H2+CH4 | 3.188×107 |

| 6 | C2H2+C2H4→C4H6 | -4.173×106 |

| 7 | 2C2H6→C2H4+2CH4 | 1.698×106 |

| 8 | C2H6+C2H4→C3H6+CH4 | -5.489×106 |

表7 乙烷丙烷裂解的反应方案[46]

Table 7 Reaction scheme for ethane propane cracking[46]

| No. | Reaction | ΔH/(kcal/mol) |

|---|---|---|

| 1 | C2H6↔C2H4+H2 | 3.257×107 |

| 2 | 2C2H6→C3H8+CH4 | -2.761×106 |

| 3 | C3H8→C3H6+H2 | 2.984×107 |

| 4 | C3H8→C2H4+CH4 | 1.974×107 |

| 5 | C3H6↔C2H2+CH4 | 3.188×107 |

| 6 | C2H2+C2H4→C4H6 | -4.173×106 |

| 7 | 2C2H6→C2H4+2CH4 | 1.698×106 |

| 8 | C2H6+C2H4→C3H6+CH4 | -5.489×106 |

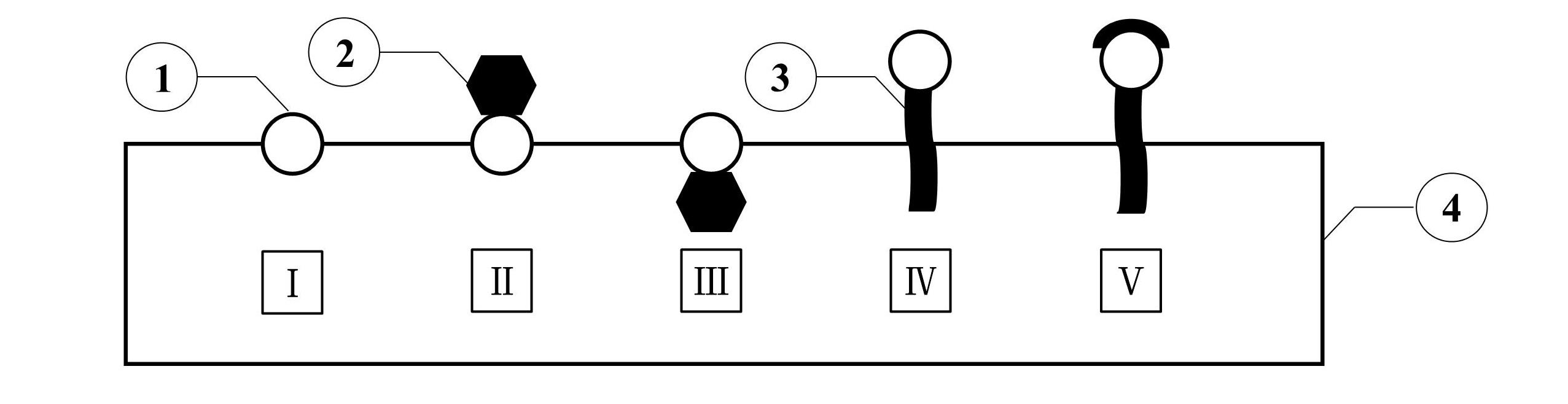

图2 催化结焦机理示意图[62]1. Catalytic particle 2. Activated carbon atom 3. Filamentous coke 4. Furnace tube surface Ⅰ. Oxidative stress cracking, catalytic particle exposure Ⅱ. Activated carbon atom adsorption Ⅲ. Carbon diffusion Ⅳ. Filamentous coke formation, catalytic particles were released Ⅴ. Carbon coated catalytic particles

Fig.2 Principle diagram of catalytic coke[62]

| No. | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Kinetic model | X+S→XS XS→C+S+nH2 | X+S↔XS XS→C+S+nH2 | X+S→XS XS→C+S+nH2 CS→eS+fC+gCS | X+S↔XS XS→C+S+nH2 CS→eS+fC+gCS |

| Model accuracy | Poor | Poor | More accurate | Accurate |

表8 催化机理动力学模型[66]

Table 8 Kinetic model of catalytic mechanism[66]

| No. | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Kinetic model | X+S→XS XS→C+S+nH2 | X+S↔XS XS→C+S+nH2 | X+S→XS XS→C+S+nH2 CS→eS+fC+gCS | X+S↔XS XS→C+S+nH2 CS→eS+fC+gCS |

| Model accuracy | Poor | Poor | More accurate | Accurate |

| 1 | Sadrameli S M. Thermal/catalytic cracking of liquid hydrocarbons for the production of olefins: a state-of-the-art review II: catalytic cracking review [J]. Fuel, 2016, 173: 285-297. |

| 2 | 赵文明. 对我国乙烯原料路线多元化发展现状及趋势探讨 [J]. 化学工业, 2018, 36(2): 1-13. |

| Zhao W M. The raw materials diversification status and trends of China ethylene industry [J]. Chemical Industry, 2018, 36(2): 1-13. | |

| 3 | 陈晓昀. 国内乙烷裂解制乙烯项目应关注问题探讨 [J]. 乙烯工业, 2019, 31(2): 6-10, 5. |

| Chen X J. Discussion on issues concerning domestic ethane cracking to ethylene project [J]. Ethylene Industry, 2019, 31(2): 6-10, 5. | |

| 4 | 徐海丰. 2018年世界乙烯行业发展状况与趋势 [J]. 国际石油经济, 2018, 27(1): 82-88. |

| Xu H F. 2018 world ethylene industry development status and trends [J]. International Petroleum Economics, 2018, 27(1): 82-88. | |

| 5 | 何盛宝, 王红秋, 王春娇. 中国进口乙烷裂解制乙烯项目前景分析 [J]. 化工进展, 2018, 37(9): 6-10. |

| He S B, Wang H Q, Wang C J. Prospect analysis of import ethane cracking projects in China [J]. Chemical Industry and Engineering Progress, 2018, 37(9): 6-10. | |

| 6 | 谭捷.我国乙烯的供需现状及发展前景 [J]. 精细与专用化学品, 2019, 27(10): 18-20. |

| Tan J. Supply and demand situation and development prospect of ethylene in China [J]. Fine and Specialty Chemical, 2019, 27(10): 18-20. | |

| 7 | Rosli M N, Aziz N. Steady state modelling of steam cracking furnace radiant section using Aspen plus [J]. Materials Today: Proceedings, 2018, 5(10): 21780-21789. |

| 8 | Zheng S, Zhang X Y, Qi C B, et al. Modeling of heat transfer and pyrolysis reactions in ethylene cracking furnace based on 3-D combustion monitoring [J]. International Journal of Thermal Sciences, 2015, 94: 28-36. |

| 9 | 詹宜泽, 詹宇. 乙烷制乙烯产业链现状及发展前景 [J]. 化工管理, 2018, (19): 9-10. |

| Zhan Y Z, Zhan Y. Status and development prospects of ethane to ethylene industry chain [J]. Chemical Management, 2018, (19): 9-10. | |

| 10 | 黄格省, 师晓玉, 张彦, 等. 国内外乙烷裂解制乙烯发展现状及思考 [J]. 现代化工, 2018, 38(10): 1-5. |

| Huang G S, Shi X Y, Zhang Y, et al. Situation of ethylene production via ethane cracking and considerations [J]. Modern Chemical Industry, 2018, 38(10): 1-5. | |

| 11 | 王子宗, 何细藕. 乙烯装置裂解技术进展及其国产化历程 [J]. 化工进展, 2014, 33(1): 1-9. |

| Wang Z Z, He X O. Progress of cracking technology of ethylene plant and its development in China [J]. Chemical Industry and Engineering Progress, 2014, 33(1): 1-9. | |

| 12 | Sadrameli S M. Thermal/catalytic cracking of hydrocarbons for the production of olefins: a state-of-the-art review I: thermal cracking review [J]. Fuel, 2015, 140: 102-115. |

| 13 | Hernández A Y. A model for the prediction of olefin production and coke deposition during thermal cracking of light hydrocarbons [D]. Medellín: Universidad Nacional de Colombia, 2012: 3-4. |

| 14 | 张凡. 乙烯裂解炉内燃烧、流动、传热及裂解反应特性数值模拟研究 [D]. 北京: 中国石油大学(北京), 2017: 4-5. |

| Zhang F. Numerical simulation of combustion, flow, heat transfer and cracking reaction in cracking furnace [D]. Beijing: China University of Petroleum (Beijing), 2017: 4-5. | |

| 15 | 许江, 马艳捷, 程中克, 等. USC裂解炉出口温度、炉管构型对循环乙烷裂解性能的影响 [J]. 现代化工, 2018, 38(10): 215-218. |

| Xu J, Ma Y J, Cheng Z K, et al. Influences of outlet temperature and furnace tube configuration to circulating pyrolysis property of ethane in USC cracker [J]. Modern Chemical Industry, 2018, 38(10): 215-218. | |

| 16 | 马嘉, 李春燕, 辛江, 等. 轻质原料裂解制乙烯路径分析 [J]. 化学工业, 2018, 36(5): 29-33. |

| Ma J, Li C Y, Xin J, et al. Analysis of light feedstock for ethylene cracker [J]. Chemical Industry, 2018, 36(5): 29-33. | |

| 17 | 黄风林. 石油天然气化工工艺 [M]. 北京: 中国石化出版社, 2011: 103. |

| Huang F L. Oil and gas chemical process [M]. Beijing: China Petrochemical Press, 2011: 103. | |

| 18 | 温翯, 郭晓莉, 苟尕莲, 等. 乙烷裂解制乙烯的工艺研究进展 [J]. 2020, 40(5): 47-51. |

| Wen H, Guo X L, Gou G L, et al. Process research and development of ethane cracking to ethylene [J]. 2020, 40(5): 47-51. | |

| 19 | 姜维. 乙烷、丙烷及其混合物相互作用机理研究 [D]. 大庆: 东北石油大学, 2014: 2. |

| Jiang W. Mechanism of interaction in ethane, propane and their mixtures [D]. Daqing: Northeast Petroleum University, 2014: 2. | |

| 20 | Fakhroleslam M, Sadrameli S M. Thermal/catalytic cracking of hydrocarbons for the production of olefins: a state-of-the-art review III: process modeling and simulation [J]. Fuel, 2019, 252: 553-566. |

| 21 | Fang Z, Qiu T, Zhou W G. Coupled simulation of recirculation zonal firebox model and detailed kinetic reactor model in an industrial ethylene cracking furnace [J]. Chinese Journal of Chemical Engineering, 2017, 25(8): 1091-1100. |

| 22 | 罗殿英. 烃类分子裂解产物分布规律的数值模拟研究 [D]. 大庆: 东北石油大学, 2011: 5-6. |

| Luo D Y. A study of the numerical simulation on the distribution of the hydrocarbon molecule's pyrolysis products [D]. Daqing: Northeast Petroleum University, 2011: 5-6. | |

| 23 | 张红梅, 顾萍萍, 南子龙, 等. 蒸汽热裂解反应动力学模型的研究进展 [J]. 化工生产与技术, 2012, 19(2): 34-36. |

| Zhang H M, Gu P P, Nan Z L, et al. Research progress on reaction kinetics model of steam pyrolysis [J]. Chemical Production and Technology, 2012, 19(2): 34-36. | |

| 24 | Zhuang X, Yu J. Modeling ethylene and propylene yield for cracking furnace based on a kind of new recurrent neural network [C]//Proceedings of the 4th International Conference on Control and Automation, 2003: 718-722. |

| 25 | Rosli M N, Aziz N. Ethane steam cracking inferential model development using artificial neural network [J]. Materials Today: Proceedings, 2019, 19: 1451-1458. |

| 26 | 张利军, 张永刚, 王国清. 石脑油裂解反应模型研究及应用进展 [J]. 化工进展, 2010, 29(8): 40-46. |

| Zhang L J, Zhang Y G, Wang G Q. Progress and prospect in modeling and simulation of naphtha cracking [J]. Chemical Industry and Engineering Progress, 2010, 29(8): 40-46. | |

| 27 | 张凯, 李奇安, 李悦. 裂解反应动力学模型研究概况 [J]. 当代化工, 2012, (7): 97-101, 105. |

| Zhang K, Li Q A, Li Y. Research survey of pyrolysis kinetics model [J]. Contemporary Chemical Industry, 2012, (7): 97-101, 105. | |

| 28 | Rice F O. The thermal decomposition of organic compounds from the standpoint of free radicals. IV. the dehydrogenation of paraffin hydrogenations and the strength of the C-C bond [J]. Journal of the American Chemical Society, 1933, 55: 4245-4247. |

| 29 | 李蔚, 张兆斌, 周丛, 等. 裂解炉管内自由基反应模型的研究进展 [J]. 乙烯工业, 2010, 22(2): 1-6. |

| Li W, Zhang Z B, Zhou C, et al. Research progress of free radical reaction model in cracking furnace tube [J]. Ethylene Industry, 2010, 22(2): 1-6. | |

| 30 | Sundaram K M, Froment G F. Modeling of thermal cracking kinetics. 3. radical mechanisms for the pyrolysis of simple paraffins, olefins, and their mixtures [J]. Industrial & Engineering Chemistry Fundamentals, 1978, 17(3): 174-182. |

| 31 | Tarafder A, Lee B C S, Ray A K, et al. Multiobjective optimization of an industrial ethylene reactor using a nondominated sorting genetic algorithm [J]. Industrial & Engineering Chemistry Research, 2005, 44(1): 124-141. |

| 32 | Froment G F, Vandesteene B, Sumedha O. Selectivities and yields in cocracking ethane and propane [J]. Oil and Gas Journal, 1979, 77(16): 87-90. |

| 33 | 邹晋, 娄强昆, 邹仁鋆. 脉冲微型反应装置上乙烷-丙烷混合裂解反应动力学的研究 [J]. 中国科学化学, 1985, 15(11): 967-974. |

| Zhou J, Lou Q K, Zou R Y. Study on kinetics of mixed cracking reaction of ethane-propane on pulse micro reactor [J]. Scientia Sinica Chimica, 1985, 15(11): 967-974. | |

| 34 | Cowperthwaite E V. Mathematical model for ethane pyrolysis in an industrial furnace [D]. Ontario: Queen's University, 2014: 7-8. |

| 35 | Geem K M V, Hudebine D, Reyniers M F, et al. Molecular reconstruction of naphtha steam cracking feedstocks based on commercial indices [J]. Computers & Chemical Engineering, 2007, 31(9): 1020-1034. |

| 36 | Van Geem K M, Zajdlik R, Reynier M F, et al. Dimensional analysis for scaling up and down steam cracking coils [J]. Chemical Engineering Journal, 2007, 134: 3-10. |

| 37 | 李晓艳. 重整拔头油的综合利用研究 [D]. 上海: 华东理工大学, 2016: 39-40. |

| Li X Y. Study on comprehensive utilization of reforming topped oil [D]. Shanghai: East China University of Science and Technology, 2016: 39-40. | |

| 38 | Zhang Y, Qian F, Zhang Y, et al. Impact of flue gas radiative properties and burner geometry in furnace simulations [J]. AIChE Journal, 2015, 61(3): 936-954. |

| 39 | Hu G H, Zhang Y, Du W, et al. Zone method based coupled simulation of industrial steam cracking furnaces [J]. Energy, 2019, 172: 1098-1116. |

| 40 | Zhang Y. Computational fluid dynamics-based steam cracking furnace optimization using feedstock flow distribution [J]. AIChE Journal, 2017, 63(7): 3199-3213. |

| 41 | Hu G H, Schietekat C M, Zhang Y, et al. Impact of radiation models in coupled simulations of steam cracking furnaces and reactors [J]. Industrial & Engineering Chemistry Research, 2015, 54(9): 2453-2465. |

| 42 | Yuan B F, Li J L, Du W L, et al. Study on co-cracking performance of different hydrocarbon mixture in a steam pyrolysis furnace [J]. Chinese Journal of Chemical Engineering, 2016, 24(9): 1252-1262. |

| 43 | 钱锋, 胡贵华, 杜文莉, 等. 用于工业乙烯蒸汽裂解炉设计验证和优化的耦合建模方法: CN103310123A [P]. 2013-09-18. |

| Qian F, Hu G H, Du W L, et al. Coupling modeling method for design verification and optimization of industrial ethylene steam cracking furnace: CN103310123A [P]. 2013-09-18. | |

| 44 | 张红梅, 徐春明, 高金森. 管式炉裂解制乙烯反应动力学模型的研究进展 [C]//第九届全国化学工艺学术年会论文集. 北京:中国石化出版社, 2005: 563-567. |

| Zhang H M, Xu C M, Gao J S. Research progress of reaction kinetics model for tube furnace pyrolysis to ethylene [C]//Proceedings of the 9th National Annual Conference on Chemical Technology. Beijing: China Petrochemical Press, 2005: 563-567. | |

| 45 | 魏巍. SRT-Ⅳ(HC)型裂解炉中HVGO裂解过程的模型化与模拟 [D]. 北京: 北京化工大学, 2006: 15. |

| Wei W. Modeling and simulation for HVGO pyrolysis process in SRT-IV(HC) cracking furnace [D]. Beijing: Beijing University of Chemical Technology, 2006: 15. | |

| 46 | Sundaram K M, Froment G F. Modeling of thermal cracking kinetics. 1. thermal cracking of ethane, propane and their mixtures [J]. Chemical Engineering Science, 1977, 32(6): 601-608. |

| 47 | Gujarathi A M, Dipesh S P, Pravar A, et al. Simulation and analysis of ethane cracking process [C]//Proceedings of International Symposium & 62nd Annual Session of IIChE in association with International Partners (CHEMCON-2009), 2009: 27-30. |

| 48 | Yancheshmeh M S S, Haghighi S S, Gholipour M R, et al. Modeling of ethane pyrolysis process: a study on effects of steam and carbon dioxide on ethylene and hydrogen productions [J]. Chemical Engineering Journal, 2013, 215/216(17): 550-560. |

| 49 | Ranjan P, Kannan P, Shoaibi A A, et al. Modeling of ethane thermal cracking kinetics in a pyrocracker [J]. Chemical Engineering & Technology, 2012, 35(6): 1093-1097. |

| 50 | Karimi H, Cowperthwaite E V, Olayiwola B, et al. Modelling of heat transfer and pyrolysis reactions in an industrial ethylene cracking furnace [J]. Canadian Journal of Chemical Engineering, 2018, 96: 33-48. |

| 51 | Feli Z, Darvishi A, Bakhtyari A, et al. Investigation of propane addition to the feed stream of a commercial ethane thermal cracker as supplementary feedstock [J]. Journal of the Taiwan Institute of Chemical Engineers, 2017, 81: 1-13. |

| 52 | 张朝环. 乙烯裂解炉内燃烧与裂解反应过程数值模拟 [D]. 天津: 天津大学, 2008: 44-58. |

| Zhang C H. Numerical simulation on the combustion and cracking reaction of ethylene cracking furnace [D]. Tianjin: Tianjin University, 2008: 44-58. | |

| 53 | 陈娟娟. 乙烯裂解炉综合数值模拟 [D]. 天津: 天津大学, 2009: 16-31. |

| Chen J J. Comprehensive Numerical simulation of ethylene pyrolyzer [D]. Tianjin: Tianjin University, 2009: 16-31. | |

| 54 | 高晓丹. 乙烯裂解炉的模拟和优化方法研究 [D]. 北京: 清华大学, 2008: 84-91. |

| Gao X D. Study on the simulation and optimization method for ethylene cracking furnaces [D]. Beijing: Tsinghua University, 2008: 84-91. | |

| 55 | 王小强, 田亮, 程中克, 等. 乙烯裂解炉模拟优化软件现状及其应用 [J]. 石油与天然气化工, 2019, 48(6): 44-48. |

| Wang X Q, Tian L, Cheng Z K, et al. Present situation and application of simulation and optimization software for ethylene cracking furnace [J]. Chemical Engineering of Oil and Gas, 2019, 48(6): 44-48. | |

| 56 | Hay G, Rasouli G, Carbognani-Arambarri L, et al. Reduce coke formation and save operating costs with optimization of DMDS into ethane cracking furnaces [J]. Hydrocarbon Processing, 2017, 96(2): 49-52. |

| 57 | Jambor B, Hájeková E. Formation of coke deposits and coke inhibition methods during steam cracking [J]. Petroleum and Coal, 2015, 57(2): 143-153. |

| 58 | Broutin P, Ropital F, Reyniers M F, et al. Anticoking coatings for high temperature petrochemical reactors [J]. Oil & Gas Science and Technology, 1999, 54(3): 375-385. |

| 59 | Amir B, Behrouz M, Vahid P. Mathematical modeling of ethane cracking furnace of olefin plant with coke formation approach [J]. International Journal of Chemical Reactor Engineering, 2018, 16(9): 1-14. |

| 60 | Schietekat C M, Sarris S A, Reyniers P A, et al. Catalytic coating for reduced coke formation in steam cracking reactors [J]. Industrial & Engineering Chemistry Research, 2015, 54(39): 9525-9535. |

| 61 | Mobarakia M, Afshangb B, Rahimpour M R, et al. Effect of cracking feedstock on carburization mechanism of cracking furnace tubes [J]. Engineering Failure Analysis, 2020, 109(1): 1-11. |

| 62 | 孙孝儒, 沈利民. 乙烯裂解炉管结焦机理及其防护措施研究进展 [J]. 腐蚀科学与防护技术, 2017, 29(5): 575-580. |

| Sun X R, Shen L M. Research progress of coking mechanism and prevention measures for ethylene cracking furnace tubes [J]. Corrosion Science and Protection Technology, 2017, 29(5): 575-580. | |

| 63 | Albright L F, Marek J C. Coke formation during pyrolysis: roles of residence time, reactor geometry, and time of operation [J]. Industrial & Engineering Chemistry Research, 1988, 27(5): 743-751. |

| 64 | 张莹莹. 乙烷裂解炉烧焦过程安全区的计算与优化操作的模拟 [D]. 天津: 天津大学, 2009: 1. |

| Zhang Y Y. Determination of safe conditions and simulation of optimum operations for decoking of ethane pyrolysis furnace [D]. Tianjin: Tianjin University, 2009: 1. | |

| 65 | Karimi H, Olayiwola B, Farag H, et al. Modelling coke formation in an industrial ethane cracking furnace for ethylene production [J]. The Canadian Journal of Chemical Engineering, 2020, 98(1): 158-171. |

| 66 | Mohamadalizadeh A, Towfighi J, Karimzadeh R. Modeling of catalytic coke formation in thermal cracking reactors [J]. Journal of Analytical & Applied Pyrolysis, 2008, 82(1): 134-139. |

| 67 | Sundaram K M, Froment G F, Van Damme P S. Coke deposition in the thermal cracking of ethane [J]. AIChE Journal, 1981, 27(6): 946-951. |

| 68 | Wauters S, Marin G B. Computer generation of a network of elementary steps for coke formation during the thermal cracking of hydrocarbons [J]. Chemical Engineering Journal, 2001, 82(1): 267-279. |

| 69 | Wauters S, Marin G B. Kinetic modeling of coke formation during steam cracking [J]. Industrial & Engineering Chemistry Research, 2002, 41: 2379-2391. |

| [1] | 金卓航 韩晓霞 刘奉宜. 结合流程仿真的甲烷化反应动力学多目标参数辨识方法[J]. 过程工程学报, 2025, 25(1): 34-43. |

| [2] | 苟荣恒 殷梦凡 郑涛 朱家伟 张睿 刘海燕 刘植昌 孟祥海. MTO副产C5+混合烯烃催化裂解制乙丙烯流程模拟[J]. 过程工程学报, 2024, 24(12): 1407-1416. |

| [3] | 张烁 关宇 尤园江 岳君容 裴世红 崔彦斌 刘姣 许光文. 耐磨球形Ni/Al2O3催化剂催化CO甲烷化反应的本征动力学[J]. 过程工程学报, 2024, 24(1): 107-116. |

| [4] | 张凯伦 焦念明 张莹 郝鹏波 张国霞 王慧 李增喜. 双金属改性ZSM-5-USY复合分子筛催化裂解正己烷制备低碳烯烃[J]. 过程工程学报, 2022, 22(4): 458-468. |

| [5] | 丁宝平 刘慧利 李法社. 小桐子壳热解及其挥发性产物特性分析[J]. 过程工程学报, 2022, 22(3): 366-375. |

| [6] | 樊炳宇 陈鑫亮 杨利 高尚 谢永健 王振峰 王平 刘瑾. 界面增容剂的结构对PLA/PP共混体系界面状态及性能的影响[J]. 过程工程学报, 2022, 22(3): 413-420. |

| [7] | 贾富华 龚斌 汪前雨 朱多银 崔彦斌. 高导热苯乙烯丙烯酸树脂复合材料制备及导热性能[J]. 过程工程学报, 2021, 21(9): 1082-1090. |

| [8] | 何星晨 王娟 张佳 万加亿 王江云 毛羽. 多组扭曲片排布方式对乙烯裂解炉管内产物收率的影响[J]. 过程工程学报, 2021, 21(4): 401-409. |

| [9] | 黄新杰 高金达 周志杰 张笑枫 胡俊杰. 凹型结构下保温材料EPS典型垂直火蔓延特性对比研究[J]. 过程工程学报, 2021, 21(11): 1315-1322. |

| [10] | 张敏 韩林 胡月月 李健 闫 冰. 改性琼脂糖微球固定化甘油脱氢酶的研究[J]. 过程工程学报, 2020, 20(5): 591-598. |

| [11] | 龙超 陈瑞 翟持 陈飞 杨春曦. 微芯片中磁性液滴的生成与操控综述[J]. 过程工程学报, 2020, 20(10): 1134-1146. |

| [12] | 陈嵩嵩 董丽 张军平 盛贵阳 张梅香 崔改静. 环氧乙烷化工设计安全事项分析[J]. 过程工程学报, 2018, 18(S1): 72-81. |

| [13] | 刘静如 金满平 赵磊 张帆 徐伟 石宁. 铁锈对环氧乙烷水溶液失控反应的影响[J]. 过程工程学报, 2018, 18(S1): 138-145. |

| [14] | 常远 郑家乐 都林 李松庚 宋文立. 流化床用树脂基球形活性炭及其VOCs吸附性能[J]. 过程工程学报, 2018, 18(5): 1112-1118. |

| [15] | 王卫 吴耀辉 黎继烈 姚跃飞. 赤霉素发酵过程动力学建模与分析[J]. 过程工程学报, 2017, 17(3): 605-612. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||